I got a ball bearing spring base from Tom the other day and decided to experiment with it as well as the NCY spring and the Kidnme shorty clutch I have sitting around.

What I found was somewhat interesting.

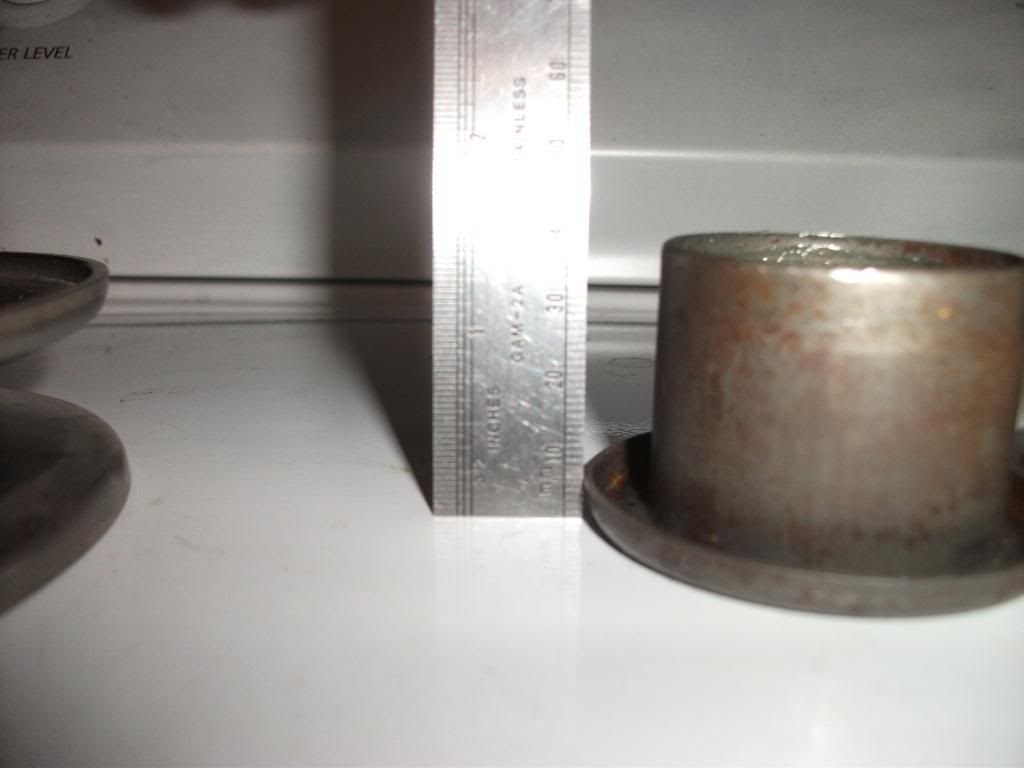

First off, the aftermarket spring base compresses any spring because of the height of the bearings and the additional bearing "race" if you will approx 9mm. I have read an increase of 15% is added to the spring rate because it's slightly compressed.

I took all measurements from the engine case to the edge of the clutch pulley "lip" when fully pulled back by hand.

No spring no clutch the pulley fully extended to the "stops" 46.5mm

Stock base shorty clutch NCY 1500 RPM spring 46mm

MRP base shorty clutch NCY 1500 RPM spring 45mm

MRP base shorty clutch stock spring 42mm

Stock base OEM clutch stock spring 46mm

Stock base shorty clutch stock spring 45mm

MRP base OEM clutch stock spring 42mm

The additional height of the MRP base causes the stock spring to bind.

With the NCY spring, this is not the case.

The OEM spring has 1 additional coil in it that the NCY doesn't. This obviously makes all the difference.

I could tell the clutch pulley/sheave does slide nicer with the bearing base. I'd bet this makes for a smoother feel while shifting.

However, the additional spring compression from the MRP base with the 1500 RPM made it really difficult to move by hand. I would think the 2 combined should be closer to a 2000 RPM spring.

So I'm going to see what a 1000 RPM spring with the base gets me. I'll bet it's closer to the 1500 spring, but with the nice smooth shift I'm looking for.

So, in conclusion, I would not run this spring base with an OEM spring if you are looking for top speed as the belt may not reach as far down the pulley as a stock set up would.